2025-05-08 https://www.aluminum-coils.com/a/large-aluminum-sheet-metal.html

Aluminum sheet metal has long been prized across numerous industries for its light weight, corrosion resistance, and versatility. However, when it comes to large aluminum sheet metal, these attributes multiply in significance, offering unmatched technological and economic benefits to fabricators, manufacturers, and engineers.

Large Aluminum Sheet Metal: Beyond Just Size

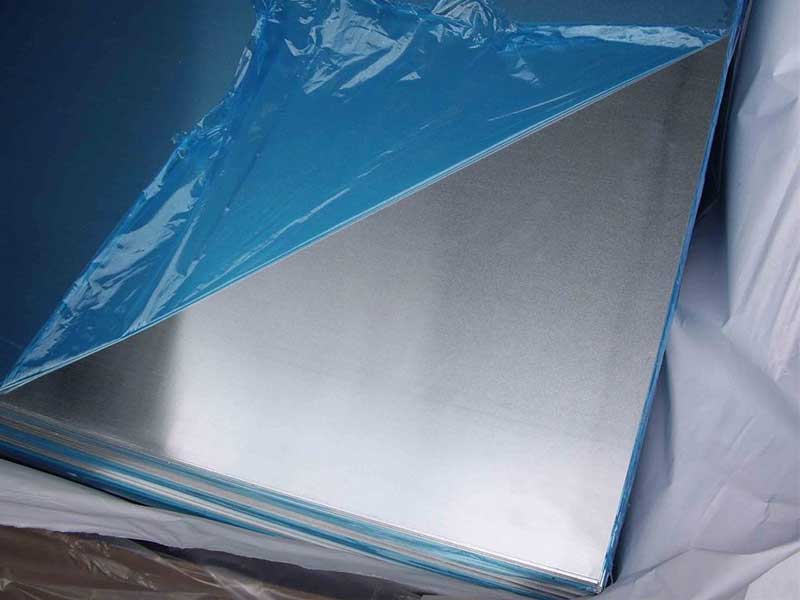

Technically, "large aluminum sheet metal" groups metal sheets with dimensions greater than standard industry sizes — often exceeding 48” x 96” and thicknesses ranging from 0.020” (0.5 mm) up to over 0.25” (6 mm), although custom sheets can be even larger. The substantial size broadens application scope, but its utility is more than just about surface area:

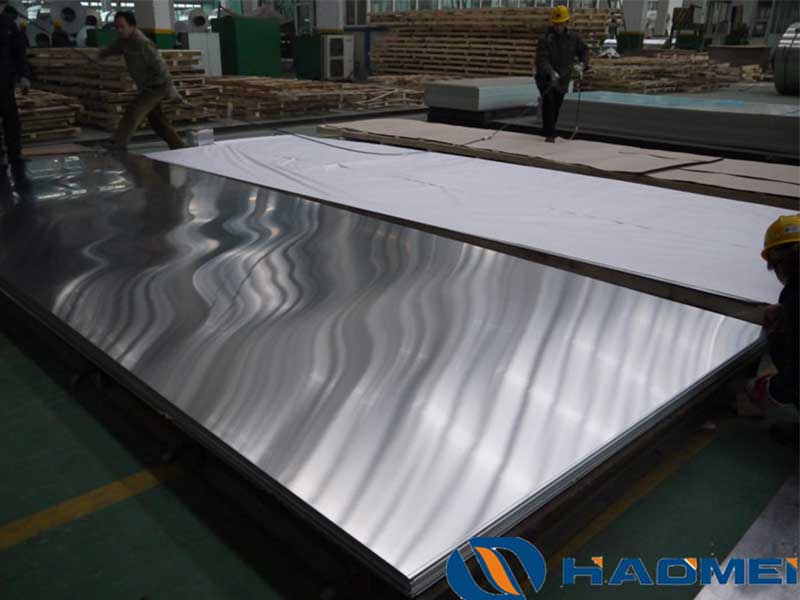

Working with large aluminum sheet metal presents unique challenges compared to smaller pieces. The sheer size necessitates specialized handling equipment; cranes and forklifts are essential, not optional, and even then, careful planning of movement and storage is crucial to prevent warping, bending, or even catastrophic failure from uneven weight distribution. Surface imperfections, often imperceptible in smaller sheets, become magnified, demanding stricter quality control measures during both the rolling process and the final inspection. We've learned the hard way that minor scratches or surface irregularities in a large sheet can lead to significant issues down the line, especially in applications requiring precise surface finish or structural integrity. Furthermore, the thermal expansion and contraction of these sheets are significant factors in fabrication; accounting for these movements during cutting, welding, and finishing processes is paramount to avoid costly rework or scrap.

Beyond the logistical hurdles, the material itself behaves differently at scale. Internal stresses become more pronounced in larger sheets, potentially leading to distortion or buckling over time, even under minimal load. This necessitates careful consideration of the alloy chosen and its temper. We've discovered that the specific grain structure and its response to various processes is vital for mitigating these issues. For example, using specific annealing techniques can significantly reduce residual stresses and improve the overall dimensional stability of a finished product. Finally, efficient cutting and processing techniques become critical given the expense and difficulty of handling these oversized pieces. Investing in high-powered, high-precision cutting equipment and

Enhanced Structural Integrity Under Uniform Load: Wide, continuous sheets distribute stress more evenly than smaller fabricated panels. The expansive surface means fewer welded joints or rivets, reducing weak points and enhancing fatigue resistance.

Improved Thermal & Electrical Performance: Large sheets enable smoother, uninterrupted paths for thermal conductivity or electrical roles in heat exchangers and conductive housings, where internal discontinuities might hinder performance.

Optimized Manufacturing Efficiency: The ability to work with a prepared large sheet reduces handling steps, minimizes material wastage, and allows automated cutting or forming processes with unprecedented precision and output speeds.

Specialized Chemical Compositions Amplify Large Sheets’ Performance

Large aluminum sheets aren’t “just bigger pieces.” Alloy choice dramatically knits functionality with size:

5000 Series Aluminum-Alloy: Rich in magnesium (3-5%), these offer exceptional corrosion resistance alongside moderate strength — ideal for marine panels or heavy-duty container floors fabricated as one seamless large sheet.

6000 Series Aluminum-Alloy: With magnesium and silicon elements, these sheets combine good strength and excellent machinability. Their profile benefits architectural cladding where both robustness and ease of bending large panels are paramount.

7000 Series Aluminum-Alloy: For aerospace or military-grade applications demanding extreme tensile leverage in large format components, this high-zinc aluminum sheet class sets a high bar despite being harder to form on large scales.

Distinct Fabrication Techniques Elevate Large Sheets

Large, oversized aluminum sheets require intersectional knowledge—in metallurgy, fabrication, and logistics:

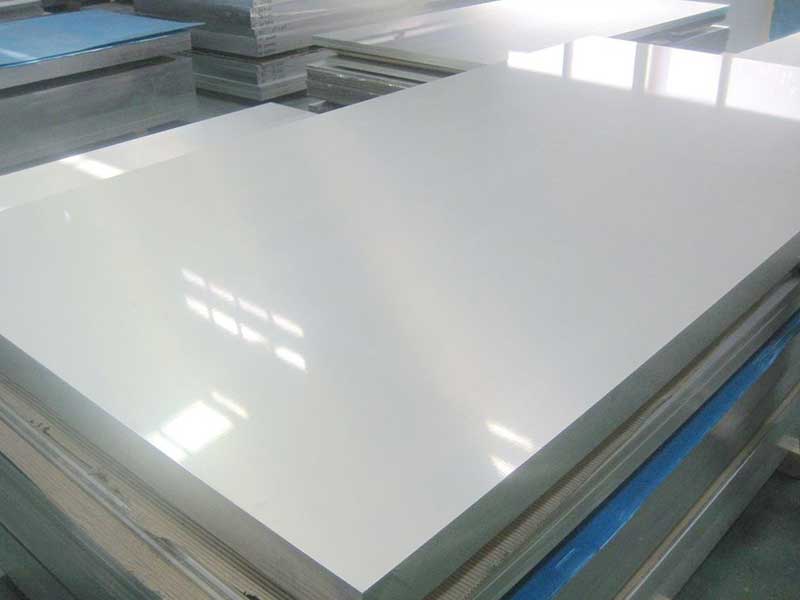

Thermomechanical Processing Strategies: Conventions evolve to tightly control tempering and rolling speeds over these large dimensions to enforce grain uniformity and preserve surface quality without warping.

Advanced Shearing and Laser Cutting: Amid expanding automated demands, precision technologies mitigate slag and dross risks, providing flawless edges — critical for aerospace skin panels and cosmetic exteriors alike.

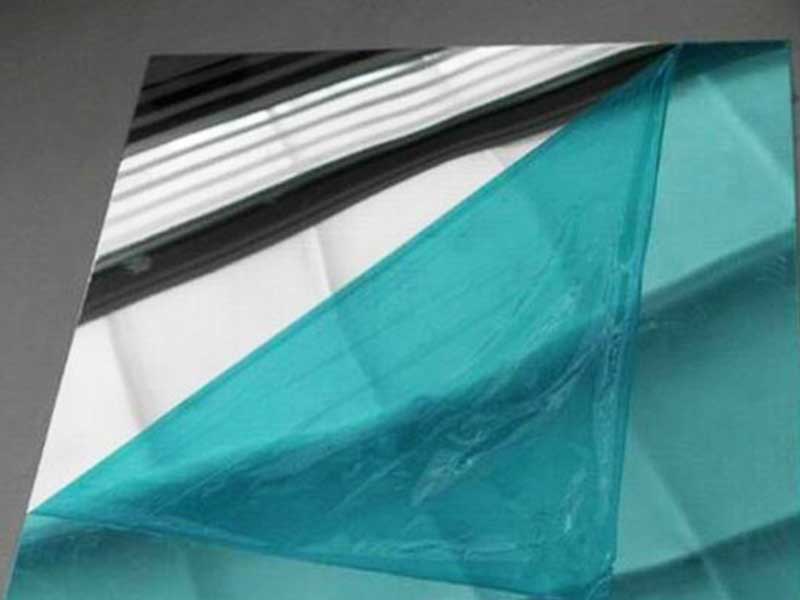

Selective Surface Treatments: Anodizing large sheets—done prior to fabrication—tip the scales for corrosion and set color preferences efficiently because batch scaling disadvantages in size matter economically for end suppliers.

Environmental Dimensions of Large Aluminum Sheet Adoption

Sustainability isn’t an afterthought. It's well integrated into decision-making via large sheet metals through:

Reduced Joint Materials and Trabajas emocionadas: Fewer parts mean fewer welding rods or riveting tactics, cutting down consumables that might demand energy society-wise for their production.

Recycling and Lifecycle Consistency: Large aluminum sheets originate from an easier molten-cycling flow in rolling mills. Less scrap and off-cuts lower carbon footprints and materias wasted.