In modern architecture, the curtain wall system stands as a symbol of innovation, combining aesthetics, functionality, and sustainability. At the heart of many curtain walls lies one fundamental component: the aluminum sheet. Aluminum**, prized for its lightweight durability, corrosion resistance, and design flexibility, transforms raw aluminum sheets into cutting-edge curtain wall panels that define contemporary building exteriors.

Why Aluminum Sheets Are Ideal Raw Materials for Curtain Wall Panels

Aluminum's rise as a preferred material for curtain wall panels is no accident. Processed from high-quality aluminum sheets, these panels serve multi-dimensional roles in building envelopes:

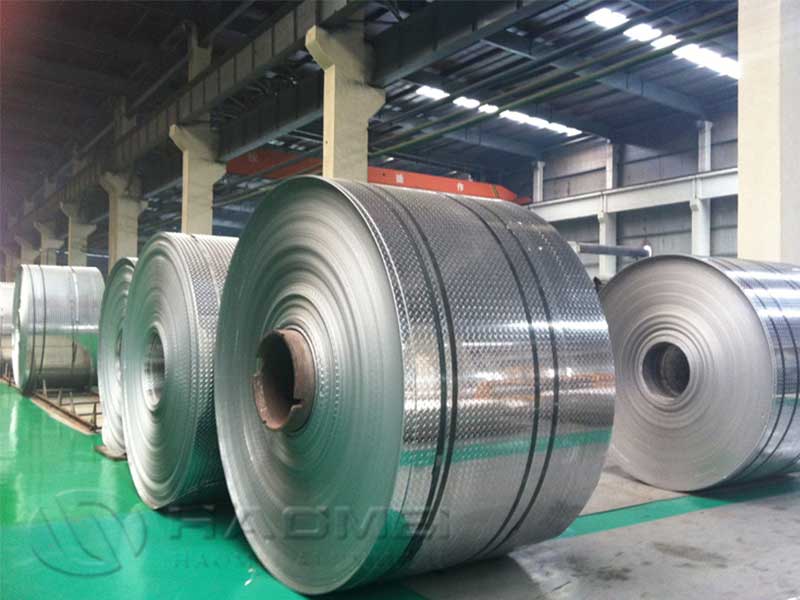

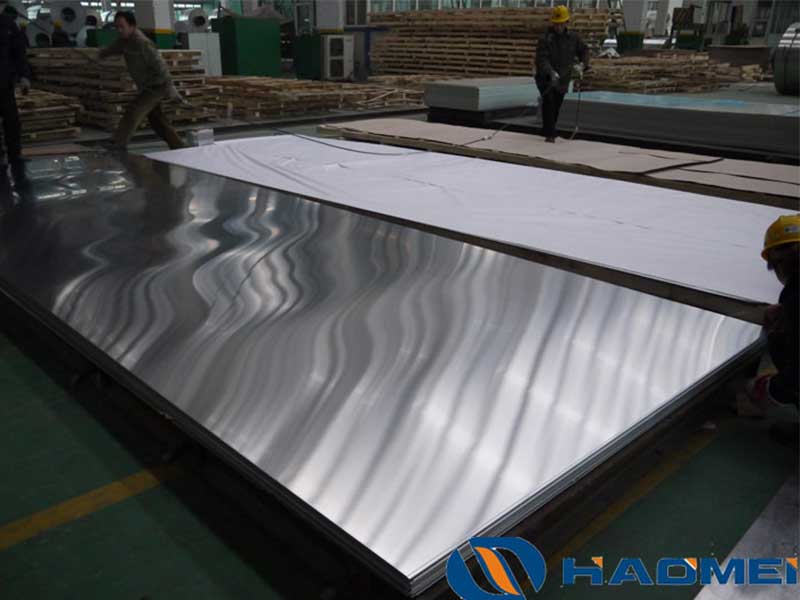

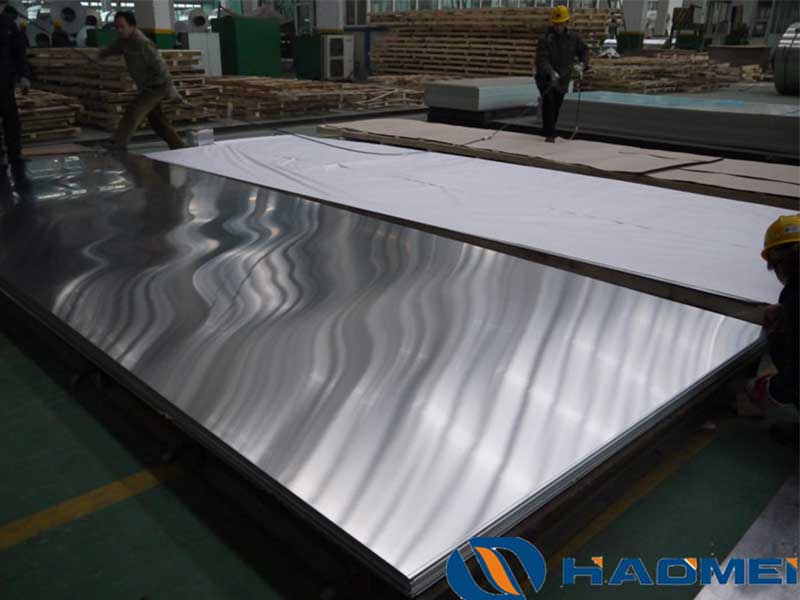

From my perspective on the factory floor, the journey of an aluminum sheet from raw coil to a finished curtain wall panel is a fascinating testament to precision engineering. We deal with a huge variety of alloys, each with subtly different properties impacting the final product's strength, corrosion resistance, and even the ease of fabrication. A seemingly minor adjustment in the rolling mill, for instance, can significantly alter the panel's flatness and thus its suitability for complex architectural designs. Witnessing the transformation – the cutting, forming, and anodizing processes – highlights the crucial role of quality control at every stage. A single flaw in the initial sheet can lead to costly rejection down the line, emphasizing the importance of consistent raw material quality.

Beyond the technical aspects, I've observed how the aesthetic appeal of these panels is driving innovation. The demand for unique colors, finishes, and patterns necessitates advanced surface treatments and pushes our team to explore new alloy compositions and fabrication methods. It's rewarding to see the final product – these sleek, modern curtain walls adorning buildings – knowing that our work, from the initial inspection of aluminum sheets to the final quality check on the finished panel, contributed to their visual impact and structural integrity. It's a constant learning process, keeping us on the cutting edge of material science and manufacturing techniques.

Structural Integrity with Lightweight DesignAluminum sheets, with their remarkable strength-to-weight ratio, provide structural support without burdening the building frame. This enables architects to design larger exterior spans and taller facades while easing load demands on foundations and core structures.

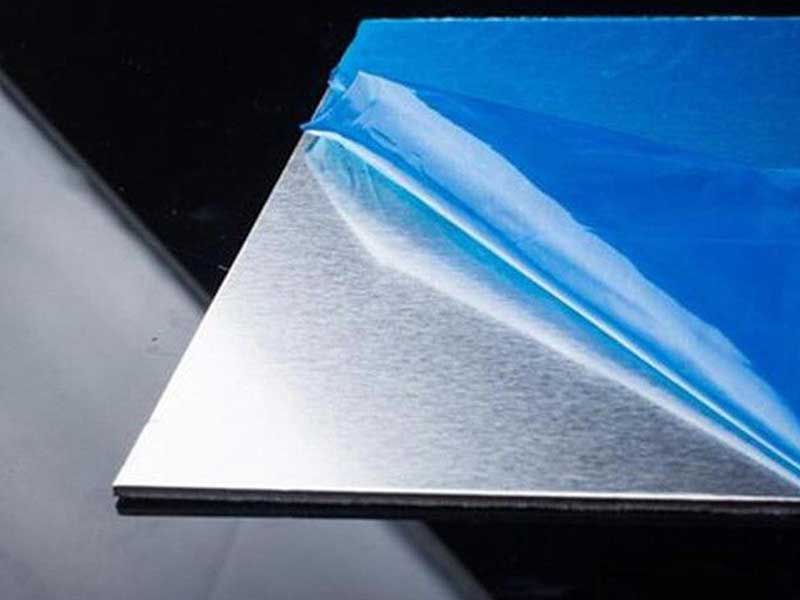

Enhanced Weather ResistanceThe anodizing or powder coating processes selectively applied on aluminum sheets produce highly weather-resistant curtain wall panels. Aluminum's natural oxide layer acts as a protective barrier against moisture, UV exposure, and pollutants—in safeguarding facades and preserving their appearance over decades.

Thermal Performance & Energy EfficiencyModern curtain walls incorporate insulated aluminum sheet panels that improve thermal breaking. Aluminum sheets act as mounting bases for thermal insulation materials, reducing heat transfer, enhancing energy efficiency, and helping buildings achieve stringent green standards.

Acoustic InsulationComplex aluminum sheet configurations, combined with cores such as mineral wool or polyethylene, offer excellent noise attenuation. This acoustic buffering is indispensable for urban high-rises wrestling with ambient noise pollution.

Technical Insights into Aluminum Sheet-Based Curtain Wall Panels

Material Specifications and AlloysCommonly, aluminum alloys in the 5000 (magnesium) and 6000 (magnesium and silicon) series are utilized due to their superior corrosion resistance and mechanical properties. Sheet thickness typically ranges from 1 mm up to 5 mm, balancing flexibility and strength preferences.

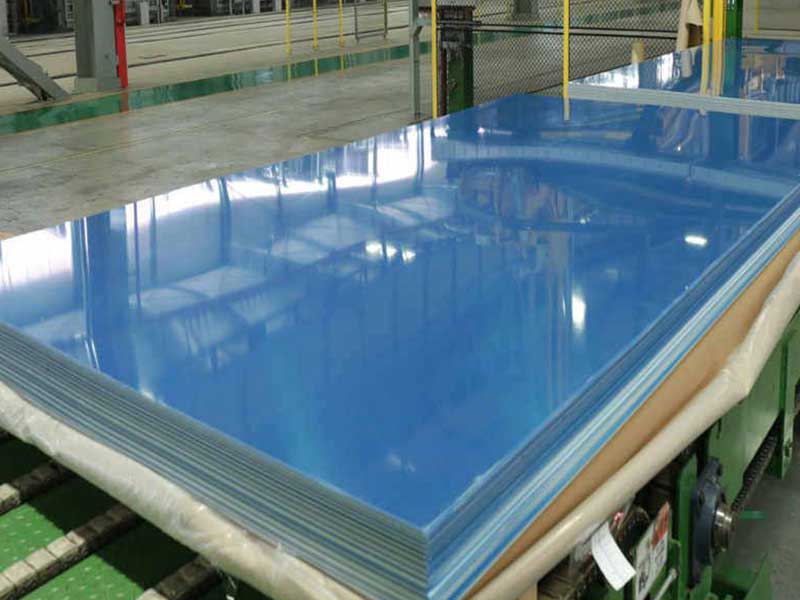

Fabrication Techniques: From Sheet to PanelAluminum sheets undergo precision cutting, bending, and roll forming to achieve crisp panel edges and shapes tailored to design specifications. Surface treatment via anodizing or ultra-durable fluoropolymer coatings ensures longevity while maintaining aesthetic vibrance.

Modular Assembly for Weather TightnessPanels are seamlessly joined with reinforced frames and gasket systems that offer airtight and watertight seals. This assembly ensures that aluminum curtain walls can withstand extreme weather and thermal cycling without compromising structural or energy performance parameters.

Integration with Glazing and Other MaterialsAluminum flat sheets can be engineered into composite panels laminated with glass, stone, or insulation core layers. This hybrid approach leveraged through robust aluminum sheet skins allows versatile, energy-efficient facade systems.

Applications and Architectural Advantages

Aluminum curtain wall panels are prevalent across building types: commercial skyscrapers, residential complexes, civic institutions, airports, and hospitals. Their adaptive nature supports trends in sustainability, modular construction, and smart buildings outfitted with sensors and shading mechanisms integrated directly into panels derived from aluminum sheets.

Aluminum’s eco-friendliness also plays a crucial role: recycled aluminum sheets retain their strength and save up to 95% of energy in the production process compared to primary aluminum alternatives, solidifying aluminum curtain gallery walls as environmentally responsible solutions.

Conclusion

Reimagining exterior cladding, aluminum curtain wall panels owe much of their hallmark properties to the versatile aluminum sheet raw material. From unmatchable lightweight structural performance and superior resistance to dynamic weather conditions, to energy-saving insulation capabilities and endlessly creative finishes, aluminum sheets enable façade engineers and architects to innovate without limits.

As the industry strives for higher standards in building resilience, sustainability, and design sophistication, the pivotal role of aluminum sheets within curtain wall panels remains a beacon of architectural progress—marrying form, function, and future-proof performance in every elegant exterior shelf and frame.