2025-06-04 https://www.aluminum-coils.com/a/3mm-perforated-aluminium-sheet.html

In the realm of metal materials, the 3mm perforated aluminium sheet stands out as an extraordinarily functional product prized across multiple industries. Offering an combination of lightweight strength, corrosion resistance, and aesthetic versatility, this product epitomizes the sophisticated utility of modern metals engineering. Today, we'll explore the technical underpinnings, materials characteristics, critical parameters, manufacturing standards, alloy conditions, and its wide array of real-world applications — delivering a holistic view of this indispensable material.

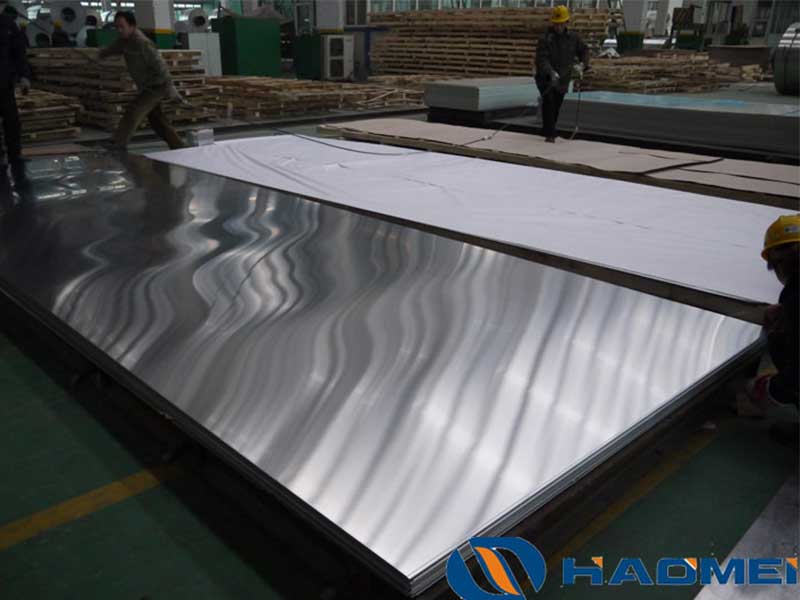

3mm Perforated Aluminium Sheet

A perforated aluminium sheet is essentially an aluminium plate manufactured with an array of precise holes punched or stamped into the surface. The perforations serve to balance airflow and light transmission with structural integrity, depending on the application.

At a thickness of 3mm, the aluminium sheet provides robust mechanical strength while still being lightweight and manipulable — optimal for monitoring, screening, filtration, and architectural uses.

Technical Parameters and Standards

- Thickness: 3.0 mm

- Hole Diameter: Variable (common sizes include 1.5mm, 3mm, to 10mm)

- Open Area: Percentage of open space; typically between 15% to 50%

- Sheet Size: Customizable, commonly 1000 mm x 2000 mm or 1250 mm x 2500 mm

- Pitch: Distance between centers of adjacent holes, ranging from 3 mm upwards

- Tolerances: Thickness ±0.1 mm; dimensional deviations ±1%

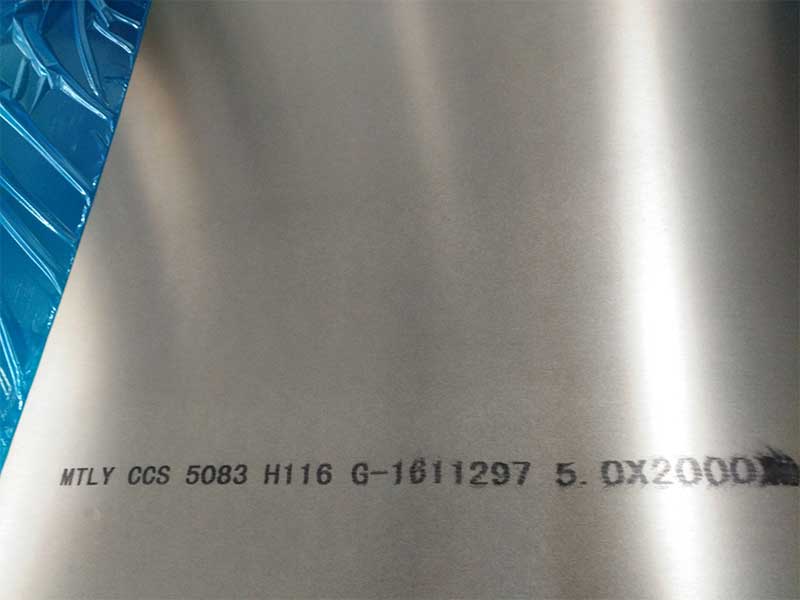

The manufacturing of perforated aluminium sheets adheres to international standards for dimension control, hole integrity, and metal properties. Typical governing standards include:

- ASTM B209: Specification for Aluminium and Aluminium-Alloy Sheet and Plate

- EN 573-3: Aluminium and aluminium alloys - Chemical composition and forms

- ISO 209-1: Rolling aluminium alloy sheet and strip – Technical delivery conditions

These standards ensure consistent physical and mechanical properties, reproducibility, and reliable performance of the perforated material.

Alloy Composition and Tempering for Performance

Perforated aluminium sheets usually utilize the 3000 series (like AA3105) or the 5000 series (like AA5052) alloys due to their tensile strength, corrosion resistance, and formability. Typical 3mm sheets are often alloy-tempered to condition H14 or H24, indicating strain hardening levels that enhance strength without compromising ductility.

Chemical Composition of Common Alloy AA5052 (% by weight)

| Element | Composition Range (%) |

|---|---|

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Manganese (Mn) | 0.1 |

| Silicon (Si) | ≤0.25 |

| Iron (Fe) | ≤0.4 |

| Copper (Cu) | ≤0.1 |

| Aluminium (Al) | Balance (~95.4 or more) |

The 3mm plate thickness with H14 temper typically features:

- Yield Strength: Around 185 MPa

- Tensile Strength: Approximately 228 MPa

- Elongation (%): About 12 - 16%

This combination renders a good balance of strength and operational flexibility critical for harsh and demanding environments.

Advantages Inherent to 3mm Thickness

- Structural Strength: Greater rigidity and load capacity compared to thinner perforated sheets, ideal for flooring, heavy-duty facades, and machine guards.

- Precision Perforation: Thicker stock allows cleanly punched holes with minimal deformation.

- Customizable Perforations: Can be produced with various patterns—including round, square, rectangular, or slotted openings—offer tailored airflow and noise control.

- Corrosion Resistance: Particularly with 5000 series alloys, effective in external and marine environments.

Applications Spanning Multiple Industries

The technical qualities of a 3mm perforated aluminium sheet enable its use in specialized sectors:

- Architectural Cladding and Sunshades: Its durability supports exterior facades; perforations improve natural ventilation while reducing solar gain.

- Industrial Machinery Protection: Acts as protective covers for motors, fans, and conveyors maintaining airflow and operational safety.

- HVAC Systems: Efficient in air diffusers, grilles, and filtration parts where strength under flow pressure is required.

- Acoustic Panels and Noise Control: Modulation of sound in industrial and commercial settings whilst maintaining mechanical strength.

- Automotive and Transportation: Used in covering ventilation ports, sound damping components, and lightweight security panels.

- Furniture and Interior Design: Adds bold industrial textural elements while remaining practical for ventilation.

Installation and Implementation Conditions

Installation typically involves cutting to size, support framing integration, and fastening methods such as rivets, screws, or welding compatible with the aluminium's tempering condition. Thermal expansion coefficients, environmental resistances, and compatibility with adjoining materials are vector elements assessed during implementation.

Before final delivery and installation, tests such as:

- Dimensional inspections

- Hole pattern conformity

- Tensile strength verification

ensure adherence to client specifications and application demands.