2025-04-28 https://www.aluminum-coils.com/a/3003-aluminum-alloy-for-ev-battery-cover.html

As electric vehicles (EVs) continue to revolutionize the automotive industry, the materials behind their critical components gain greater significance. Among these, the battery cover plays a pivotal role not just as a protective shell, but as a vital contributor to the overall performance, safety, and efficiency of the EV’s power system. Enter 3003 aluminum alloy—a material that, while often overlooked, presents a uniquely balanced solution for EV battery covers.

Why 3003 Aluminum Alloy?

From a materials science standpoint, 3003 aluminum alloy is primarily known for its exceptional corrosion resistance, superior workability, and moderate strength. It belongs to the non-heat-treatable AMg1 series (1xxx series alloys alloyed with manganese), ensuring consistent mechanical properties and enhancing longevity—for components exposed to the environmental challenges faced by EV undercarriages.

What differentiates 3003 alloy for EV battery sensitive applications is twofold:

- Its ability to withstand environmental stresses over long service lives without additional protective treatments.

- Its excellent thermal conductivity paired with lightweight characteristics, crucial for maintaining the ideal operating temperature of battery cells.

Functional Highlights in EV Battery Covers

-

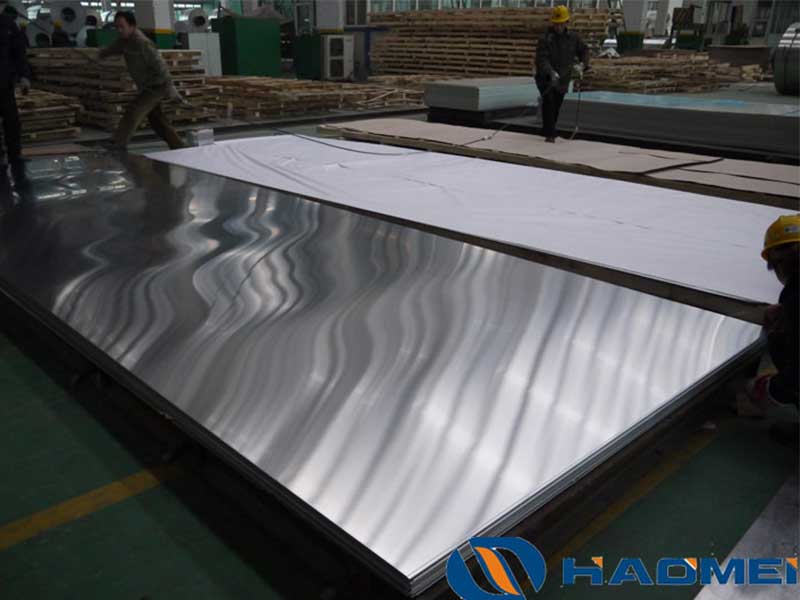

Mechanical Protection: 3003 aluminum sheets, often rolled to tailored gauges, provide robust mechanical protection against impacts from road debris, moisture ingress, and thermal expansion effects. Despite not being the highest strength alloy available, 3003 nearby alloys strike an optimum weight-to-strength ratio essential for EV efficiency paradigms.

-

Corrosion Resistance: Battery compartments inevitably face exposure to salts, humidity, and chemical residues resulting in corrosion challenges. 3003’s intrinsic manganese addition substantially enhances its natural oxide layer defense, ensuring minimal maintenance and increased lifespan for battery covers.

-

Thermal Management: Effective heat dissipation is critical to avoid overheating in EV batteries. 3003's aluminum matrix, known for its high thermal conductivity (~160-170 W/m·K), aids passive cooling by distributing heat uniformly, mitigating hotspots without adding the bulk or complexity of artificial cooling enhancements.

Tailored Applications Beyond Coverage

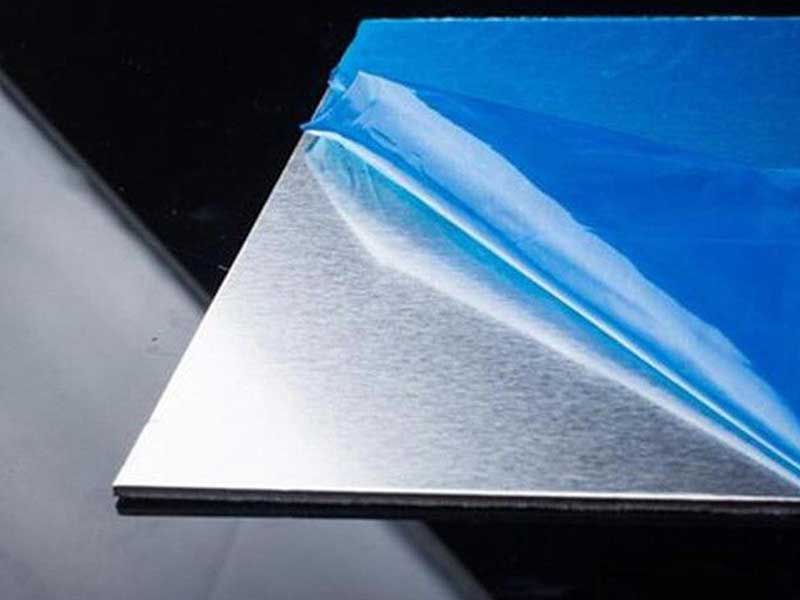

Laser cutting and stamping technologies expedite shaping 3003 aluminum sheets with tight tolerances. Manufacturers leverage anodizing and polyurethane coating finishes to elevate aesthetic and mechanical properties without compromising 3003’s lightweight nature.

Beyond protective covers, its formability has driven adoption in battery mounting plates and flexible venting grills designed to maintain structural buoyancy with minimal air impedance—highlighting this alloy’s versatile nature in evolving EV battery enclosures.